Website: http://www.famobs.eu/

Currently the vast majority of polymeric adhesive materials in electronic products are bonded using a variety of methods, such as infra-red, UV-curing, thermo-compression or convection heating. The common drawbacks of these techniques are that they take a long time and include heating up a large number of components on the whole PCB.

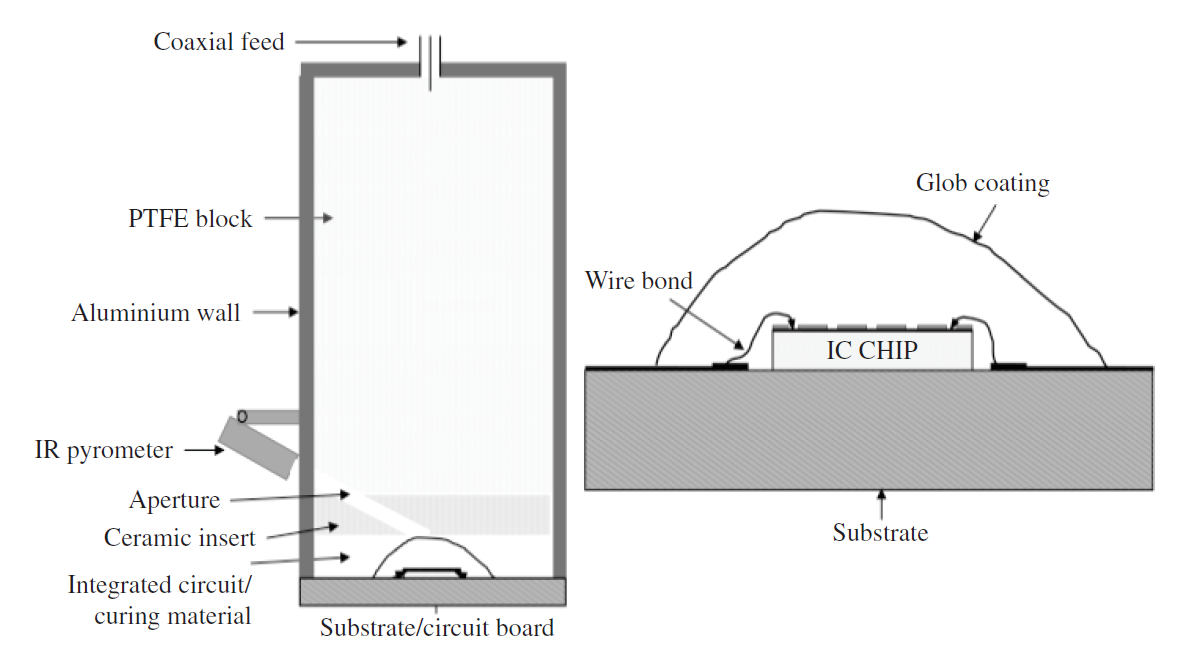

The main objective of Famobs project was to develop an extremely rapid, energy efficient process that produces a high quality cure of adhesives used in electronics industry, whilst minimising stresses that can lead to failures. Used technology is. By this novel technology, which is based on an open-ended microwave oven, it is able to bond just one component at a time. This method is especially suitable for components sensitive to long exposure at high temperatures.

Eesti Innovatsiooni Instituut’s part of the project included studying the cure kinetics of insulating and conducting epoxy resins used in encapsulation and bonding of microelectronic devices. Used methods were differential scanning calorimetry and dynamic mechanical analysis. These analyses provided data for creating optimal cure profiles for open-ended microwave system. EII also carried out the reliability tests of electronic components bonded by microwave and conventional heating. The results showed that components bonded by microwave demonstrated higher reliability than those cured in traditional convection oven.

The results of Famobs project have been introduced to scientific and industrial community of electronics industry in numerous scientific conferences and trade fairs.