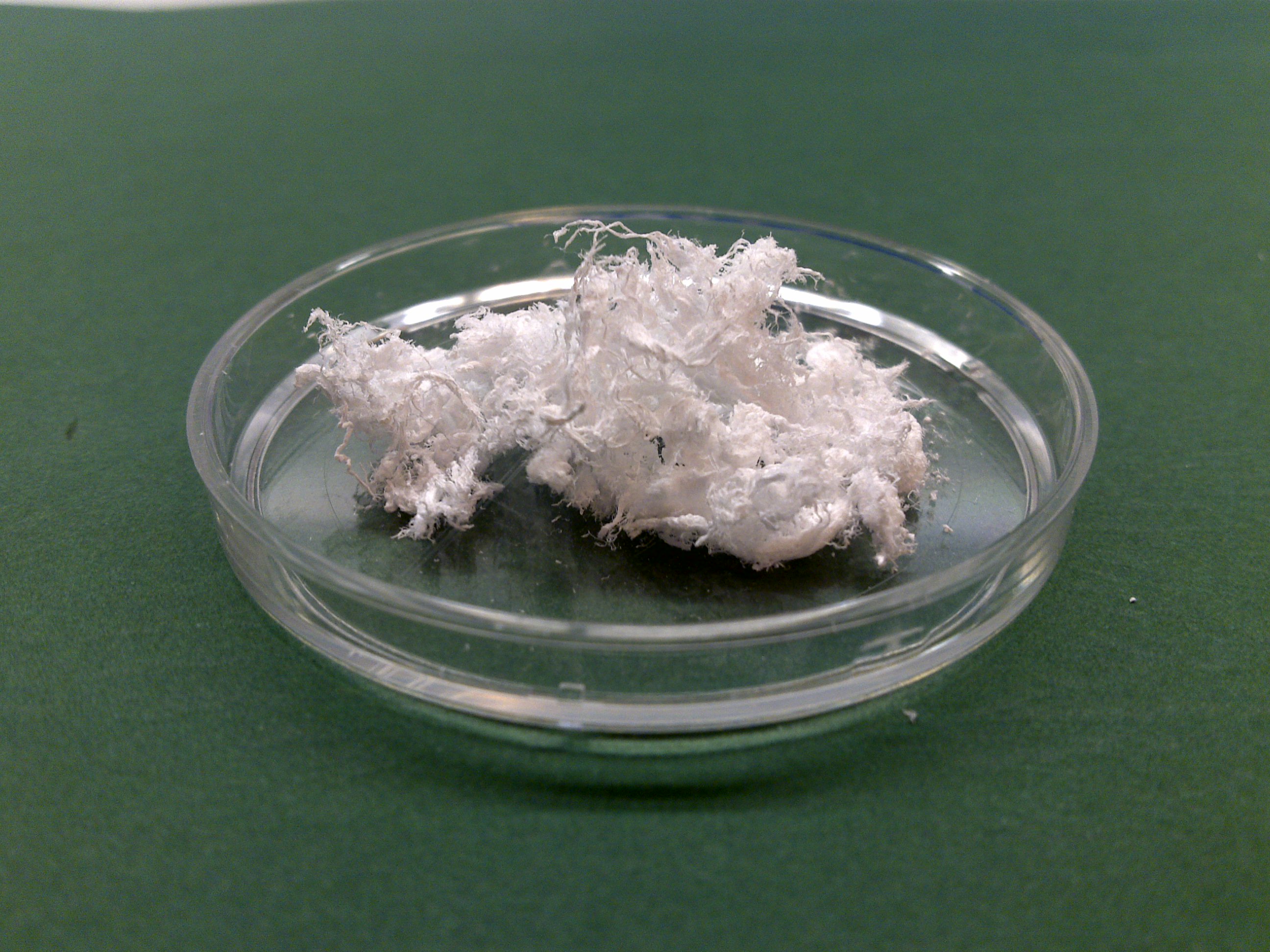

The purpose of the OkraVision project was to replace animal based and expensive hyaluronic acid (HA) with cheaper and plant based okra pectin in medical and cosmetic applications. This was achieved by developing an industrial process for extraction and purification of a transparent colourless fluid with unique viscoelastic properties from okra fruits. This okra pectin also called as RGGA (Rhamnopyranose–Galactopyranose–Galactopyranosyluronic Acid) is a 100% natural product produced in an environmentally friendly way, which has proven to be nearly free from proteins (protein content < 5 ppm) and non-toxic. Water solutions of RGGA can easily be used in the composition of skin care and hair care products as moisturizer or gel forming agent.

Eesti Innovatsiooni Instituut developed the process for extraction and purification of okra pectin. The main challenge of that work was to find the optimum process conditions in order to achieve required material properties. That process enables to produce a pectin with one of the highest molecular weights of approximately 1 MDa among this type of materials at this kind of purity level. EII also designed, assembled, and tested the bench scale production line of the developed process.